Search

Search

1419 results were found.

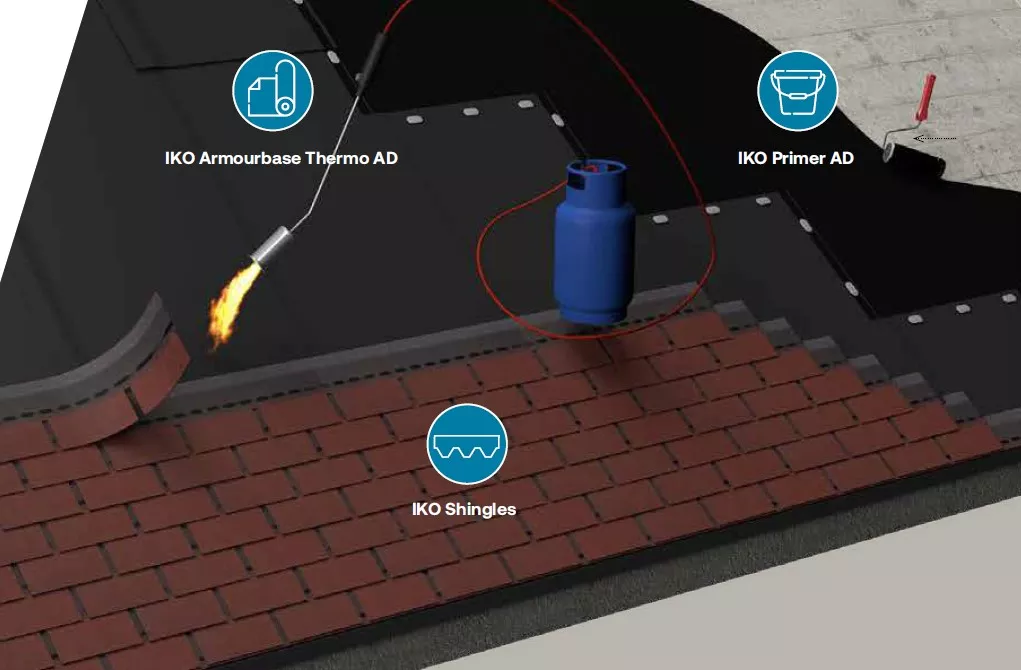

Application of shingles on top of the membrane:

All types of IKO shingles can be used and combined with this method. Start with the precutting of shingles for diagonal application and prepare the starter strip as well. It always helps if you prepare a few shingles before. Get the torch with propane ready and follow all safety rules and regulations when working with an open flame. Very important is to flame only the membrane and not the surface of shingles.

Shingles have to be laid to the melted layer of modified bitumen when the polypropylene mat fabric disappears after torching. The core of the membrane contains polyester which means the underlayment is very durable. At the same time the underlayment is also very flexible because of the modified polymers in the bitumen. Wind-seal dots or self-adhesive parts on shingles will be activated and sealed by the heat of the sun.

Remember: do not make joints and connections between the shingles close to the valley or to any details where a lot of water accumulates! When the shingles are not glued properly on the surface of Armourbase Thermo AD, you can always lift this shingle and flame the membrane again. The membrane is 2,5 mm thick and the head-lap of the shingles will then stick adequately.

Some installation tips for low slope and curved dormers:

- Always use a self-adhesive Armourbase Stick or Armourbase Pro Plus underlayment for parts with slopes from 9,5° to 20°

- For the vertical dormer wall it is very handy to use these underlayments as well

- Use only the necessary amount of nails to fix an underlayment on flatter parts of dormers

- For slopes between 4° - 9,5° use Armourbase Thermo AD and install shingles without the nails

- With every valley on the dormer or slope inclination where Closed-Cut method should be applied, follow the rule of overlapping the shingles from the lower slope to the higher slope

- With IKO Thermo System and torch-on installation apply shingles up to 15° maximum, because from 15° you can use the standard nailing method

- Don’t forget to use Shingle Stick for all roof details, roof penetrations and especially for metal flashings

Resume on dormers

Many people invest in dormer roofs as they can transform dark, stuffy loft spaces into bright and spacious living areas. Although dormer roofs require major alterations to a roof structure, the payoff is definitely worth the effort.

And your complete roof is covered with 1 single esthetical solution: You can choose any favorite shingle from the complete professional IKO Shingles range.

Interested in the product mentioned in this blogpost?

Keeping your roof in good condition is a crucial home maintenance task. Buckled shingles can quickly lead to interior leaks causing damage to your walls and creating the need for major repairs. If this happens, your roof needs to be repaired quickly to prevent further damage and increased repair costs.

What are buckled shingles?

Bitumen roof shingles occasionally show buckles along the length of courses up the roof. First of all it is important to know that buckling is not the failure of shingles.

IMPORTANT!

Bitumen roof shingles have never been proven to buckle by themselves. Buckling is the result of shingles being distorted due to movement of the roof deck on which they were applied.

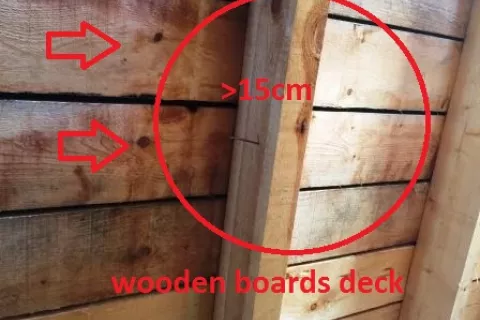

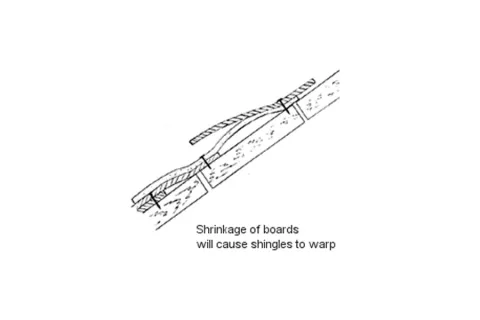

Roof decks that result in buckling of the overlying shingles are typically made out of lumber (also known as “board” or “plank” decks). Wooden boards or planks shrink or swell depending on their moisture content. Adjacent boards on the deck, even though securely nailed to the roof rafters, can shrink or swell at different rates. Shingles nailed to these wooden decks are usually held in place by two rows of roofing nails, each row often fastened into two separate boards. This is often the case when the board width exceeds the shingle exposure, eg. 20 cm boards vs. 14,3 cm shingle exposure. Differential shrinking/swelling of adjacent roof boards can therefore result in buckling of the overlying shingles. Just put a paper on the table and slide the left and right side 2 mm to the center at the same time. The paper curls and the same can happen with shingles on a lumber deck roof.

For this reason, the installation of shingles to wet wooden boards is not recommended. All wood lumber must be properly conditioned to be at moisture equilibrium. Also remember that the width of boards must always be less than 15 cm!

However vertical wrinkles/buckles can also occur on the shingle roof even when the deck is made from OSB/plywood boards without adequate spacing between boards. The minimum spacing for dilatation is > 3 mm.

Vertical wrinkles

Shrinkage of boards

Incorrect spacing between OSB boards