Search

Search

1419 results were found.

The thickness of the roof deck in relation to the span

During fastening of the wooden roof constructions, the roof rafter spacing depends on temporary and constant roof loads an on form of roof. It ranges from 600 mm up to 1500 mm. Depending on the roof rafter spacing, different preparatory layers of different thicknesses and materials are used. Please check your local building codes or static calculations. The following table is only a guideline.

| Roof rafter spacing (mm) | Min. thickness of plywood (mm) | Min. thickness of OSB-3 (mm) | Min. thickness of board (mm) |

| 600 | 12 | 12 | 20 |

| 900 | 18 | 18 | 23 |

| 1200 | 21 | 21 | 30 |

| 1500 | 27 | 27 | 37 |

Tips reducing the problem of wooden deck

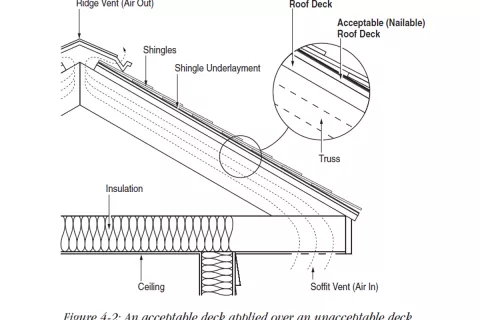

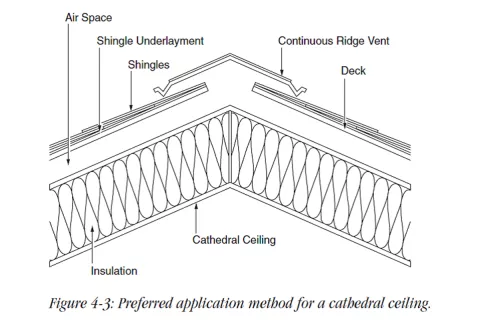

- Properly ventilate the attic. This eliminates the amount of moisture absorption by deck panels and thereby reduces the amount of swelling and shrinking of the wood. This wood movement often causes the the buckling problems with shingles.

- Leave the roof sheathing panels (plywood, OSB) to acclimate to local humidity levels before installation. This reduces swelling after the panels are installed and avoid buckling problems with shingles.

- Space deck panels 3 mm apart on all sides when fastening them to the roof framing.

- Immediately cover the roof panels with an underlayment after installation in order to keep the wood dry.

Unacceptable decks

- Cementitious wood fiber

- Gypsum plank

- Lightweight concrete

- Insulation boards

These materials are not acceptable as a roof deck for direct application of IKO shingles. These products are not likely to provide a proper surface for nails to hold the bitumen shingles. Direct shingle application can lead to over-driven or under-driven nails. Over-driven fasteners can damage the shingle, increasing the chance of wind blow-off and leakage due to wind driven-rain or ice-dam backup.

The heads of under-driven nails, or of those that back out, may prevent shingles from sealing, reduce the wind blow-off resistance, and puncture the shingle tabs above, leading to leaks.

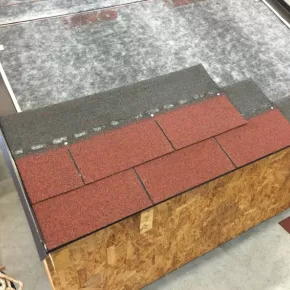

These roof surfaces must be covered with an acceptable decking material, with ventilation as required, prior to the application of IKO shingles.

In the next paragraphes, you'll be more informated about spacing shingles.

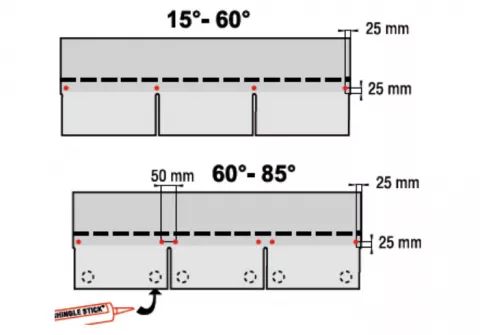

For Superglass 3Tab shingles use galvanized 25 mm long roofing nails.

The nail position is shown here. >>>

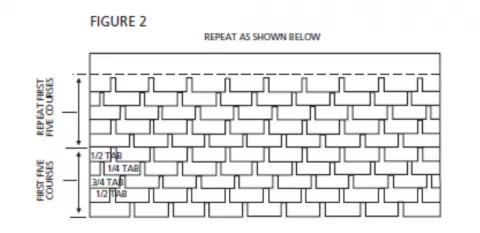

Prepare the starter by cutting off the tabs from a Superglass 3Tab shingle.

Cut half a tab from the 1st starter and nail down to the drip edge. Starters must be overhanged about 1 cm over the drip edge and sealed with mastic.

Random spacing can be achieved by removing different amounts from the rake tab of succeeding courses compared to classic installation method where there is removed ½ a tab.

You have to follow these general rules:

1. The width of any rake tab should be at least ¼ a tab.

2. Cutout centerlines of any course should be located at least ¼ a tab laterally from the cutout centre line in both the course above and the course below.

3. The rake tab widths should not repeat closely enough to cause the eye to follow a cutout alignment.

Interested in the product mentioned in this blogpost?

You don’t like the way your hips and ridges look when you use the classic method for hexagonal shingles? Don’t worry, we have another look and feel for you. Check out our following tips!