Search

Search

1419 results were found.

Poor quality

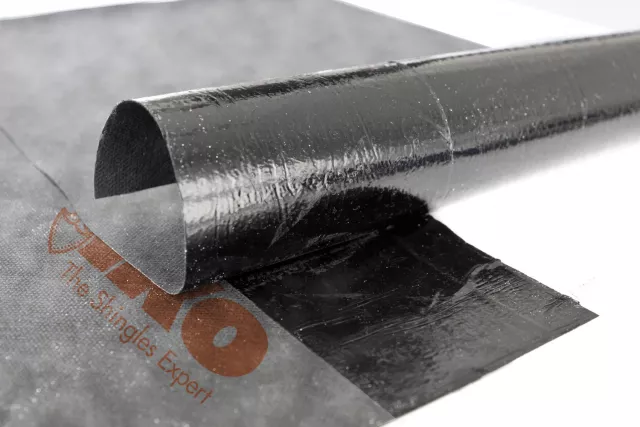

Poor quality underlayments absorb more water. Water absorption can cause wrinkling as the product expands. These wrinkles may telegraph through to the roof covering products, such as thinner bitumen shingles. Underlayment as felt paper is not recommended to apply over roof decking. Water and moisture from a wet underlayment may be absorbed by the roof deck, which can cause problems with expansion and contraction of the deck. The typical result of this failure is wrinkled shingles.

UV exposure and resistance of underlayment

Anywhere the underlayment is exposed directly to sunlight, UV radiation will accelerate its deterioration. Even though an underlayment can serve as a temporary, short-term roof cover, it’s necessary to install shingles over this underlayment within 2 or 3 weeks. UV radiation can make the polypropylene fabric peel off first; however the bitumen part will still be watertight. Anyhow aesthetically it doesn’t look good. So installing the shingles as soon as possible is highly recommended.

<<< Failure regarding of UV exposure

Remember:

The underlayment is a key component of the roofing system. The price difference between underlayment options usually adds up to a few hundred euros in your overall roof replacement project. If you are investing in high quality IKO shingles that will improve your home’s value for years to come, choosing a better quality, more durable, water-resistant underlayment is well worth the extra cost. That is why IKO the professional range of Armourbase underlayments is highly recommended.

Want to see the high quality of our Armourbase underlayments before making your decision? Or are you having difficulties deciding between two types of Armourbase?

Interested in the product mentioned in this blogpost?:

Providing a solid roof starts at the base: a roof deck suitable for the nailing and installation of shingles. The type, grade, thickness and installation of materials used for roof decks should conform to the requirements of the relevant local building codes of practice and regulations.

The roof deck should be a stable, smooth and solid surface where shingles can be easily and, more important, securely installed. The roof deck must be strong to:

- Support the roofing materials and workers.

- Safely resist impact loads, such as a pile of shingles.

- Hold constant loads, such a heavy snow.

- Provide resistance to wind force.

- Anchor the nails.

All of these conditions must remain effective during the service life of each application of shingles.

Let’s take a look at 3 roof deck materials we suggest.

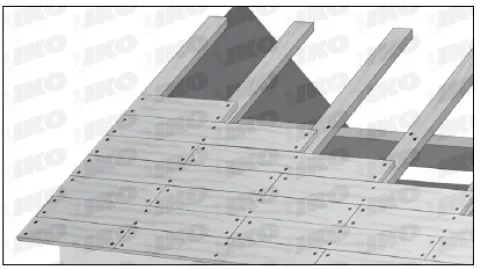

1. Sheathing boards or plywood

Sheating boards are made from thin layers of wood adhered together, each with its grain at right angles to adjacent layers for greater strength and dimensional stability. Usually there are an odd number of layers so that the grain of the outside layers run together.

Points of attention during installation:

- Install the boards with staggered vertical joints, parallel to the ridgeline. The vertical joints between boards must be supported along the whole length and nailed down well.

- Ensure sufficient support with a maximum of 600 mm in between two rafters.

- Plywood panels should be installed with 3 mm spacing between them (unless stated otherwise by the manufacturer).

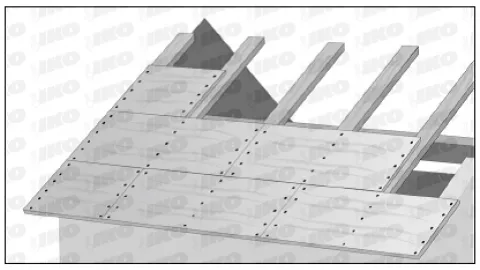

2. Oriented strand board (OSB)

Cross-orientated layers of thin rectangular wooden strips or strands, compressed and bonded together with waterproof exterior-grade binders, are formed into wide mats. The layers are oriented like plywood and may have three to five layers. The outside layers are longitudinally arranged to increase the strength and stiffness in the direction of the alignment, that is, the long direction across the rafters or trusses.

OSB is available for structural applications and for non-load-bearings uses. In Europe there are two basic grades available which are suitable for shingled roof structures.

- OSB/3: For load-bearing applications in humid conditions.

- OSB/4: For heavy-duty load-bearing applications in dry or humid conditions.

For shingled roof structures only, OSB/3 or OSB/4 can be used. The OSB panels should be also installed with 3 mm spacing between them. It is not necessary with tongue & grove locking system. Remember, panels can absorb some moisture, and then expand which can cause buckling, ridging or sagging.

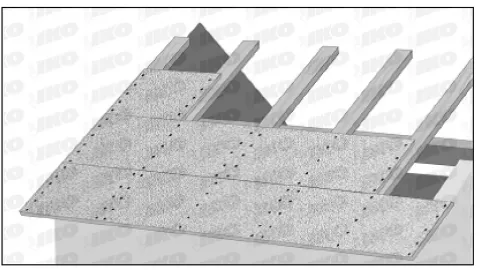

3. Wood boards

Instead of sheathing boards, solid wooden boards can be used as well. However, to minimize the effects of distortion, make sure that the boards are not wider than 150 mm and approximately 24 mm thick.

It is important to stagger the board joints. When a number of adjacent boards join on the same support/rafter, it is possible for deck movement due to distortion to a crack line in the shingles. All wood boards must be properly conditioned to be at moisture equilibrium. Never use undried, recently stripped, concrete-form lumber.

The number of fasteners should be sufficient to prevent buckling. Each board must be fastened with at least two nails in each rafter.