Search

Search

1419 results were found.

Victorian PLUS

The new Victorian PLUS information:

| Shingle name | Old item number | Old m² | Old bundles/pallet | New item number | New m² | New bundles/pallet | Presumable delivery availability |

| Victorian PLUS Black (01) | 76070201 | 2 m² | 66 | 78070301 | 2 m² | 66 | Week 46 |

| Victorian PLUS Tile Red (10) | 76070210 | 2 m² | 66 | 78070310 | 2 m² | 66 | Week 46 |

Diamant PLUS

The new Diamant PLUS information:

| Shingle name | Old item number | Old m² | Old bundles/pallet | New item number | New m² | New bundles/pallet | Presumable delivery availability |

| Diamant PLUS Black (01) | 76110201 | 2 m² | 60 | 78050201 | 2 m² | 60 | Week 29 |

| Diamant PLUS Amazon Green (03) | 76110203 | 2 m² | 60 | 78050203 | 2 m² | 60 | Unknown |

| Diamant PLUS Tile Red (10) | 76110210 | 2 m² | 60 | 78050210 | 2 m² | 60 | Unknown |

| Diamant PLUS Slate (31) | 76110231 | 2 m² | 60 | 78050231 | 2 m² | 60 | Week 30 |

Superglass 3TAB

The new Superglass information:

| Shingle name | Old item number | Old m² | Old bundles/pallet | New item number | New m² | New bundles/pallet | Presumable delivery availability |

| Superglass 3TAB Black (01) | 76000001 | 3 m² | 51 | 78000201 | 2 m² | 87 | Week 27 |

| Superglass 3TAB Amazon Green (03) | 76000003 | 3 m² | 51 | 78000203 | 2 m² | 87 | Week 49 |

| Superglass 3TAB Dual Brown (07) | 76000007 | 3 m² | 51 | 78000207 | 2 m² | 87 | Week 32 |

| Superglass 3TAB Tile Red (10) | 76000010 | 3 m² | 51 | 78000210 | 2 m² | 87 | Week 30 |

| Superglass 3TAB Sky Blue (16) | 76000016 | 3 m² | 51 | 78000216 | 2 m² | 87 | Unknown |

| Superglass 3TAB Slate (31) | 76000031 | 3 m² | 51 | 78000231 | 2 m² | 87 | Week 22 |

| Superglass 3TAB Earthtone Cedar (49) | 76000049 | 3 m² | 51 | 78000249 | 2 m² | 87 | Unknown |

| Superglass 3TAB Harvard Slate (50) | 76000050 | 3 m² | 51 | 78000250 | 2 m² | 87 | Unknown |

| Superglass 3TAB Eastern Grey (51) | 76000051 | 3 m² | 51 | 78000251 | 2 m² | 87 | Unknown |

| Superglass 3TAB Dual Black (52) | 76000052 | 3 m² | 51 | 78000252 | 2 m² | 87 | Week 20 |

| Superglass 3TAB Autumn Brown (53) | 76000053 | 3 m² | 51 | 78000253 | 2 m² | 87 | Week 38 |

| Superglass 3TAB Aged Redwood (54) | 76000054 | 3 m² | 51 | 78000254 | 2 m² | 87 | Week 23 |

| Superglass 3TAB Riviera Red (55) | 76000055 | 3 m² | 51 | 78000255 | 2 m² | 87 | Week 29 |

Superglass Biber

The new Superglass Biber information:

| Shingle name | Old item number | Old m² | Old bundles/pallet | New item number | New m² | New bundles/pallet | Presumable delivery availability |

| Superglass Biber Black (01) | 76160301 | 3 m² | 51 | 78160201 | 2 m² | 87 | Week 10 |

| Superglass Biber Amazon Green (03) | 76160303 | 3 m² | 51 | 78160203 | 2 m² | 87 | Unknown |

| Superglass Biber Dual Brown (07) | 76160307 | 3 m² | 51 | 78160207 | 2 m² | 87 | Week 33 |

| Superglass Biber Tile Red (10) | 76160310 | 3 m² | 51 | 78160210 | 2 m² | 87 | Week 32 |

Superglass Hex

The new Superglass Hex information:

| Shingle name | Old item number | Old m² | Old bundles/pallet | New item number | New m² | New bundles/pallet | Presumable delivery availability |

| Superglass Hex Black (01) | 76060801 | 3 m² | 45 | 78060401 | 3 m² | 45 | Week 29 |

| Superglass Hex Dual Brown (07) | 76060807 | 3 m² | 45 | 78060407 | 3 m² | 45 | Week 39 |

| Superglass Hex Tile Red (10) | 76060810 | 3 m² | 45 | 78060410 | 3 m² | 45 | Unknown |

| Superglass Hex Tile Red Ultra (20) | 76060920 | 3 m² | 45 | 78060520 | 3 m² | 45 | Week 39 |

| Superglass Hex Amazon Green Ultra (23) | 76060923 | 3 m² | 45 | 78060523 | 3 m² | 45 | Week 46 |

| Superglass Hex Dual Brown Ultra (27) | 76060927 | 3 m² | 45 | 78060527 | 3 m² | 45 | Week 23 |

Coiled Nails BOSTITCH

Be faster and save time and money! The roofer applies shingles 10 times (!) faster with a nailgun filled with coiled nails in comparison with loose nails.

IKO supports fast roofers and offers coiled nails from BOSTITCH available in 2 lengths: 25 and 31 mm.

IKO Armourbase Go Underlayment

On all pitches, IKO recommends that an underlayment must be used underneath the roof shingles.

IKO Armourbase GO Underlayment is an economical, good quality underlay and comes with 30 m on a roll.

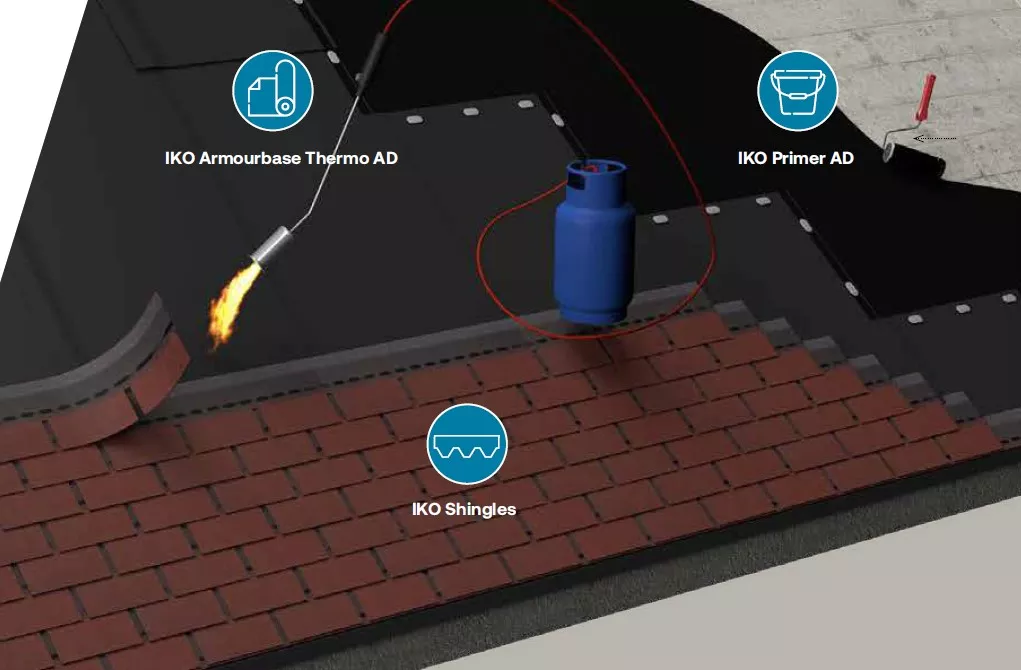

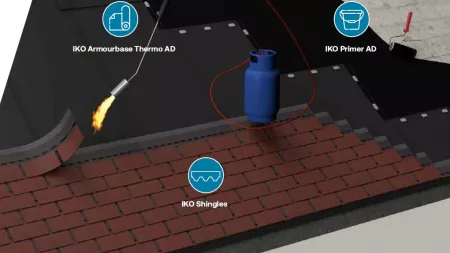

The concept consists of

- a primer for the roof deck and

- a thermo-adhesive and heat activated waterproofing membrane,

- where all residential IKO shingles can be adhered to the membrane (no nailing required!)

IKO Armourbase Thermo AD is an aesthetical solution for low sloped roofs in:

- OSB (min. 4° - max. 15°)

- or concrete (min. 4° - max. 45°)

with a secure concept system, finished with IKO shingles.

IKO Armourbase Thermo AD is a modern thermo-adhesive membrane.

The heat activated membranes of IKO Armourbase Thermo AD can be used with success in a wide range of waterproofing applications such as very low sloped roofs with concrete or wooden deck structure where bitumen shingles are applied without nail fixation. This membrane presents numerous and important advantages, such as easy application with consequential savings on time and the possibility to apply the material on surfaces which are not suitable to open flame.

| Length | 7,5 m |

| Width | 1,0 m |

| Thickness | 2,5 mm |

| Type of reinforcement | Reinforced polyester |

| Upper face finish | Polypropylene mat / Selvedge PE silicon release film |

| Lower face finish | PE silicon release film |

| Flexibility at low temperature | NPD |

| Tensile strength L/T | 400/300 N/50 mm |

| Elongation at break L/T | 35/35 % |

| Nail shank tear resistance L/T | 120/120 N |

| Dimensional stability | 0,3 % |

| External fire resistance | Class F ROOF |

| Reaction to fire | Class F |

| Watertightness | 60 kPa |

| Water vapour transmission | 100000 µ |

| Peel resistance at 180° on APP shingle | 50 N |

| Peel resistance at 90° on wood support | 70 N |

IKO Primer AD is a bituminous water based primer which helps block dust and reduces concrete porosity.

The product provides good adhesion, penetration of the substrate and above all that it is formulated with water, therefore it is not flammable and is not dangerous to use.

This product is odorless.

Primer AD

| Aspect | Liquid |

| Color | Brown |

| Density at 20° C in kg/l | 0,98 - 1,08 |

| Drying time out of dust | Approximately 20 min. (+20°C) |

| Drying time to touch | Approximately 90 min. (+20°C) |

| Dry residual at 130° C | 30% ±5 |

| Yield | 200/300 gr/m² depending on the substrate absorption |

| Flammability point | Not flammable |

| Packaging | 20L |

Mechanical fixing is a concrete screw with plate for fixation of Armourbase Thermo AD

for slopes 15°-45°

Recommended length into concrete min. 35 mm.

Pre-drilling is necessary. Use a drill diameter Ø 5,0, 5,2 or 5,5 mm for pre-drilling. The drill diamenter is dependant on the quality of the concrete.

Drilling depth: a minimum of 10 mm deeper than the lenght of the screw.

Mechanical fixing

| Technical characteristics | Screw EFHD-63045 | Plate DVP-EF-8040N |

| Diameter | 6,3 mm | 80 x 40 mm |

| Diameter hole | - | 6,5 mm |

| Length | 45 mm | - |

| Thread | 40 mm | - |

| Head type/point type | Torx T25 / Ricoh point | - |

| Packaging | 1000 pcs | 500 pcs |

Ideal solution for…

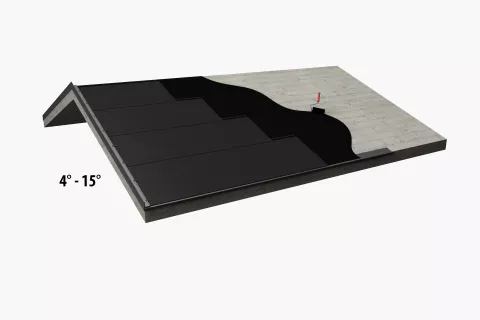

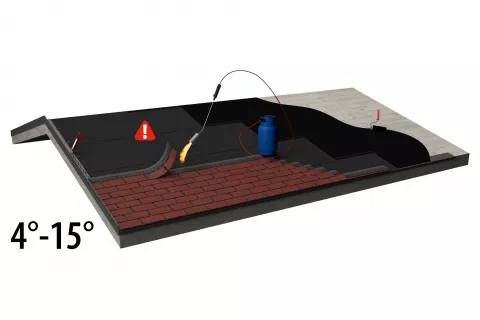

- Low slope wooden deck: Slopes between min. 4° and max. 15° need to be applied horizontally without the Armourbase Thermo AD being affixed mechanically on overlapsbeing affixed mechanically on overlaps.

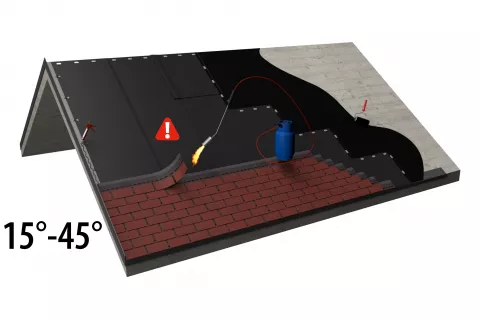

- Concrete deck: Horizontal application without mechanical fixing on slopes between min. 4° and max. 15°. For steeper slopes (max. 45°), vertical application with mechanical fixing of the membrane with screws (+ metal plate) on the overlaps is mandatory.

- Thermal insulation on concrete / OSB shingle roof (min. 4°- max. 15°): The thermal insulation must be applied and mechanicaly fixed on the concrete deck or on the OSB deck only for slopes between 4° and 15°. In these cases Armourbase Thermo AD must also be fixed on overlaps because of the underlayment’s adherence to insulating elements.

- Renovation existing flat roofs (> 4°): (only if the roof is dry, clean and watertight) Primer AD + mechanical fixation needed to install this concept.

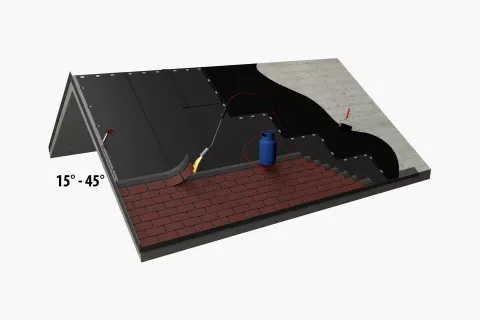

How to apply the torch on system?

Application of the underlayment on a wooden deck

Apply the membrane parallel with the eaves - vertical and horizontal overlaps should be min. 10 cm. Set the roll of Armourbase Thermo AD and remove the release film from the back. In warm, sunny weather the underlayment will stick with the wooden deck in a short time.

For slopes between 4° - 15° it is not necessary to fix the underlayment on overlaps. It is advisable to go with proper metal flashings at the eaves and rakes.

Provide horizontal and vertical overlaps 10 cm between the sheets and make sure to remove the side selvedge release foil. After application use a suitable roller and apply pressure over all overlaps.

The adhesion of Armourbase Thermo AD will start with the application of bituminous shingles by torch-on.

Application of the underlayment on a concrete deck

Apply the membrane parallel with the eaves - vertical and horizontal overlaps should be min. 10 cm. The position of Armourbase Thermo AD on the concrete deck with slopes higher than 15° should be perpendicular to the eaves.

The concrete deck must be primed with the Primer AD (bituminous primer) before the application. Set the roll of Armourbase Thermo AD and remove the release film from the back. In warm, sunny weather the underlayment will stick with the primed concrete deck in a short time. In cold weather you can help to set the Armourbase Thermo AD underlayment with a hot air gun or a torch.

For slopes between 4° - 15° it is not necessary to fix the underlayment on overlaps. For concrete decks with slopes between 15° - 45°, fixation is mandatory. This can be ensured with screws and metal pressure plates for concrete. There is a need to pre-drill holes every 30 cm on overlaps. It is advisable to go with proper metal flashings at the eaves and rakes. Provide horizontal and vertical overlaps 10 cm between the sheets and make sure to remove the side selvedge release foil. After application use a suitable roller and apply pressure over all overlaps.

The adhesion of Armourbase Thermo AD will start with the application of bituminous shingles by torch-on.

Horizontal "Armourbase Thermo AD" application on low sloped concrete deck (4°-15°)

Vertical "Armourbase Thermo AD" application on concrete deck (15°-45°) with mechanical fixing

Contact us for more information on the Armourbase Thermo AD torch on membrane system

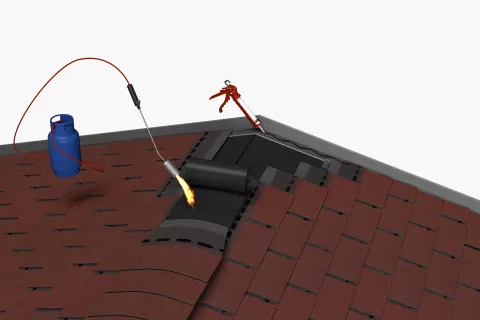

Application of bituminous roof shingles on wooden and concrete deck

This shingle application is similar to the regular shingle application concept which starts with a starter strip (a shingle with tabs cut off). Apply by heating/flaming the top layer of Armourbase Thermo AD until the polypropylene mat fabric disappears and the top bitumen coating is melted.

Lay the shingle to the melted top adhesive layer of the membrane in its proper place. If necessary, lift the upper part of the shingle with a trowel. Heat up the section of the membrane just underneath the lifted shingle. The back of the shingle should be warmed in order to get the best possible adhesion.

Continue with the diagonal installation of shingles, without using nails. It’s not necessary to torch the shingles from the top. Excessive heat can damage shingles. Essentially shingles are applied for aesthetic reasons only and the waterproofing properties derived from the roofing membrane. For the torch-on method and slopes up to 45° the fixation of shingles with nails is not necessary.

The Armourbase Thermo AD membrane will bring about the total, monolithic adherence between the support and the bituminous shingles.

Torch only on the upper face of the membrane and stick the shingles in the activated Armourbase Thermo AD. Do not torch the shingles!

Torch-on application of shingles on OSB wooden deck on slope between 4° and 15°

Torch-on application of shingles on concrete deck on slope between 4° and 15°

Torch-on application of shingles on concrete deck on slope between 15° and 45°

Hips and ridges on a wooden deck

With hip and ridges, the underlayment is already covered with shingles. Therefore hips and ridges are installed by gluing the parts. For the hip or ridge, the Armourvent Multi ventilation can be applied from a 4° slope.

Armourvent Multi must be glued on both sides with the IKO Shingle Stick and then nailed to the wooden deck. Hereafter the shingle capping will be applied over it the same way as with a roof > 15°.

In special cases, when the insulation is between the wooden deck and shingles (the warm roof) and the pitch of this roof is between 4° - 15°, the mechanical fixing is mandatory.

Then the best and most recommended solution will be to torch APP shingles over this structure.

For slopes between 4° and 15°, IKO recommends installing an extra OSB or wooden wedge and raising the ridge with Armourvent Multi ventilation. This avoids water infiltration in case of ponding water close to this ridge.

Hips and ridges on a concrete deck

On a concrete deck, a piece of 30 cm is trimmed from Armourbase Thermo AD and torched on the top part of the roof over the last rows of shingles. Then the capping can be torched over this membrane. Given the density and thermal mass of concrete decking, ventilation is not required in the air space beneath the deck.

Application on concrete roof deck

Application on wooden roof deck

Armourbase Thermo AD membrane

| Height | 7,5 m |

| Width | 1,0 m |

| Thickness | 2,5 mm |

| Type of reinforcement | Reinforced polyester |

| Upper face finish | Polypropylene mat / Selvedge PE silicon release film |

| Lower face finish | PE silicon release film |

| Cold flexibility | NPD |

| Tensile strength L/T | 400/300 (±20%) N/50 mm |

| Elongation at break L/T | 35/35 (±15)% |

| Nail shank tear resistance L/T | 120/120 (±30%) N |

| Dimensional stability | ≤ 0,3% |

| External fire resistance | Class FROOF |

| Reaction to fire | NPD |

| Watertightness | ≥ 60 kPa |

| Vapour transmission | ≥ 100.000 µ |

| Peel resistance at 180° on APP shingle | ≥ 50 N |

| Peel resistance at 90° on wood support | ≥ 50 N |

Primer AD

| Aspect | Liquid |

| Color | Brown |

| Density at 20° C in kg/l | 0,98 - 1,08 |

| Drying time out of dust | Approximately 20 min. (+20°C) |

| Drying time to touch | Approximately 90 min. (+20°C) |

| Dry residual at 130° C | 30 (± 5) % |

| Yield | 200/300 gr/m² depending on the substrate absorption |

| Flammability point | Not flammable |

| Packaging | 20L |

Mechanical fixing

| Technical characteristics | Screw EFHD-63045 | Plate DVP-EF-8040N |

| Diameter | 6,3 mm | 80 x 40 mm |

| Diameter hole | - | 6,5 mm |

| Height | 45 mm | - |

| Thread | 40 mm | - |

| Head type/point type | Torx T25 / Ricoh point | - |

| Packaging | 1000 pcs | 500 pcs |

IKO Roof Bracket

The IKO Roof Bracket is suitable for roofs up to 45°.

The use of IKO Roof Brackets results in an easy installation and removal without damaging of shingles. It is designed to hold a 50 x 150 millimeters wooden plank and is bench-tested to support up to 600 kilograms of load.