Search

Search

1419 results were found.

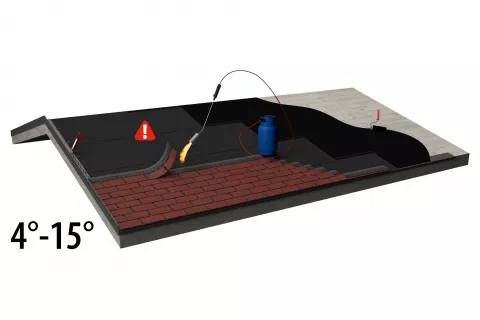

Torch-on application of shingles on OSB wooden deck on slope between 4° and 15°

Torch-on application of shingles on concrete deck on slope between 4° and 15°

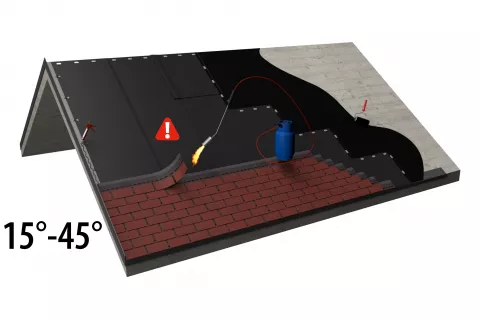

Torch-on application of shingles on concrete deck on slope between 15° and 45°

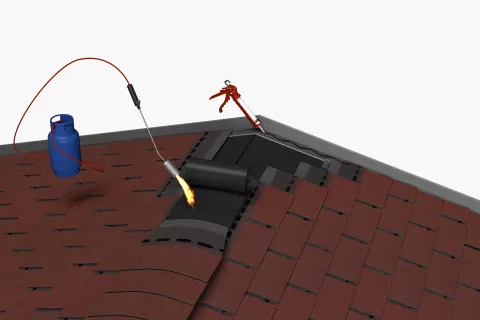

Hips and ridges on a wooden deck

With hip and ridges, the underlayment is already covered with shingles. Therefore hips and ridges are installed by gluing the parts. For the hip or ridge, the Armourvent Multi ventilation can be applied from a 4° slope.

Armourvent Multi must be glued on both sides with the IKO Shingle Stick and then nailed to the wooden deck. Hereafter the shingle capping will be applied over it the same way as with a roof > 15°.

In special cases, when the insulation is between the wooden deck and shingles (the warm roof) and the pitch of this roof is between 4° - 15°, the mechanical fixing is mandatory.

Then the best and most recommended solution will be to torch APP shingles over this structure.

For slopes between 4° and 15°, IKO recommends installing an extra OSB or wooden wedge and raising the ridge with Armourvent Multi ventilation. This avoids water infiltration in case of ponding water close to this ridge.

Hips and ridges on a concrete deck

On a concrete deck, a piece of 30 cm is trimmed from Armourbase Thermo AD and torched on the top part of the roof over the last rows of shingles. Then the capping can be torched over this membrane. Given the density and thermal mass of concrete decking, ventilation is not required in the air space beneath the deck.

Application on concrete roof deck

Application on wooden roof deck

- Durable heavy duty steel construction

- Centrally mounted and welded steel ribbing plate with extra heavy-duty welds which make them over 30% stronger than regular fixed roof brackets

- Made from 3 millimeter steel and features a double-welded base plate fulcrum and reinforced ribbing that eliminates roof bracket flexing under excess load conditions

- Provides a built-in cord and hose management system that helps prevent accidental tripping or falling caused by entanglement in air hoses and electrical cords on roof decks

- Has a unique steel plate welded into the load bearing fulcrum of each bracket that dramatically improves the strength and durability of the bracket compared to conventional roof brackets

- Smooth edges and rounded corners will not cut hands or work area

- Finished with powder black exterior paint

MOUNTING AND DISMOUNTING OF ROOF BRACKETS

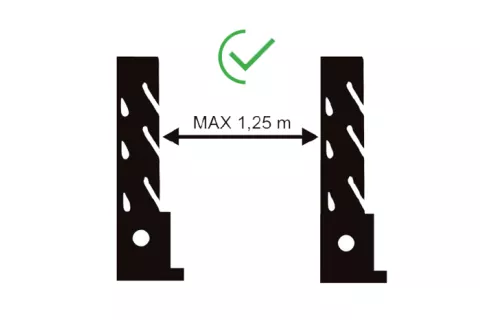

Place the brackets the way that maximum horizontal spacing between them is 1,25 m

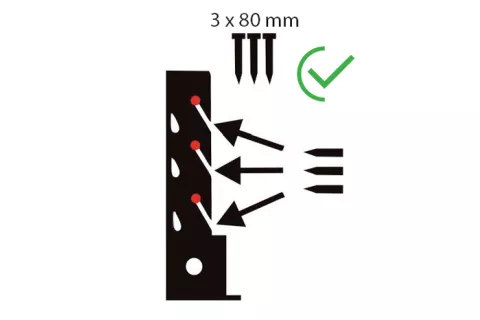

Secure each bracket with three construction nails with a minimum size of 3.1 x 80 mm. All nails must be positioned in the top of the nail slots and to the rafter.

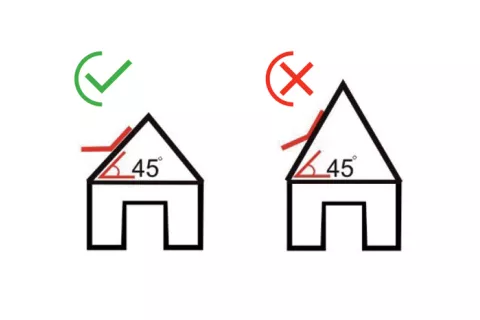

The brackets must be attached to a 45-degree roof so that the work platform is level. Do not use the work platform if it is not level.

To remove the brackets, push them upwards.

How to use IKO Roof Brackets?