Search

Search

1419 results were found.

Installation of planks

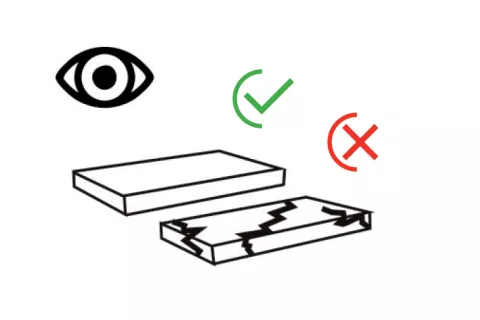

Before and after each use, check that the plank if is not damaged. Use only straight grained, clear wood.

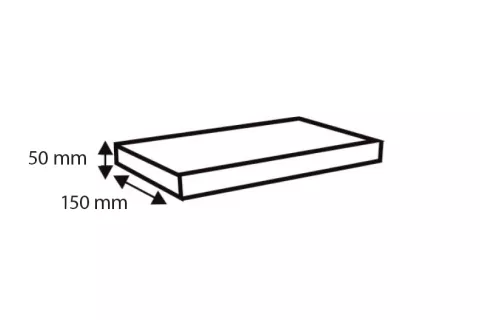

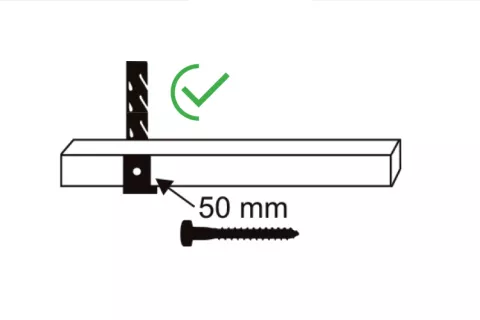

Use a wooden plank of standard dimensions 150 x 50 mm. The plank cannot be thinner than 50 mm!

Secure the plank to the brackets with screws or nails with a minimum length of 50 mm. Use the hole provided at the short-hooked end of the bracket.

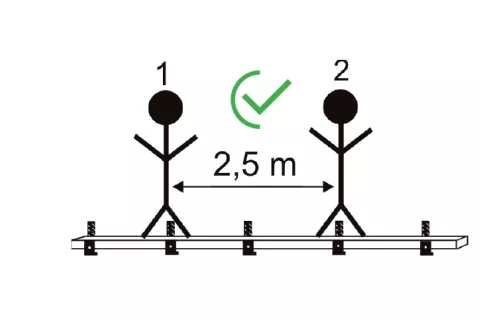

Maximum one person per 2,5 m of plank length.

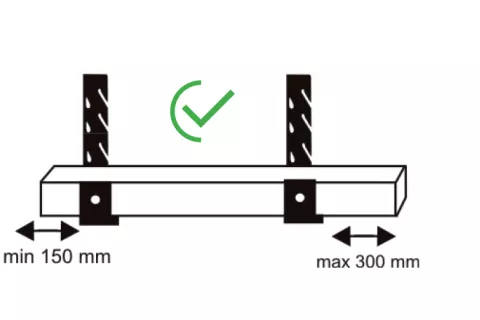

The end of the plank must extend at least 150 mm beyond the roof but not more than 300 mm.

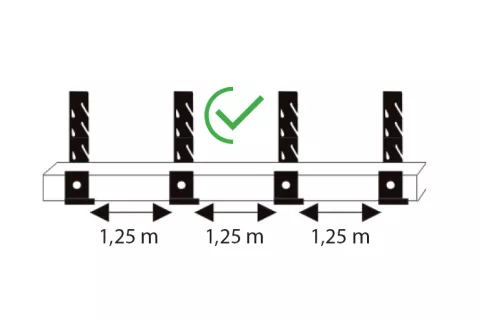

For longer planks use additional brackets every 1,25 m.

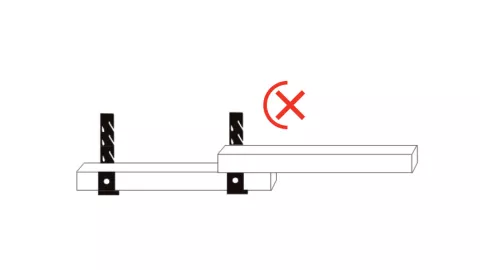

Do not place more than one plank on one pair of brackets.

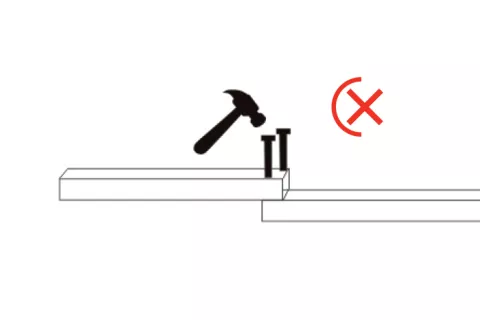

Do not nail planks together.

Application instructions

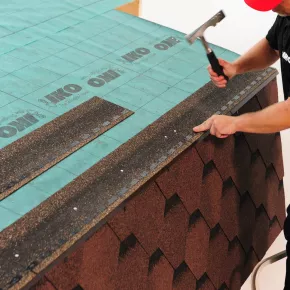

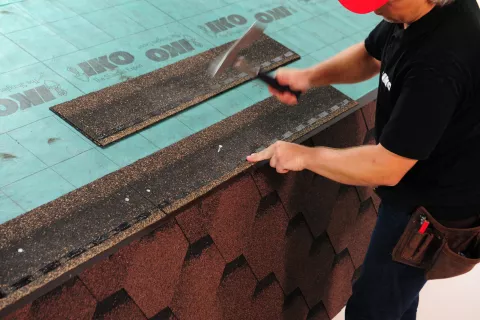

Begin the starter strip by cutting the strip half a tab short so that its joints will not line up with the joints of the first course of shingles.

The starter strip should overhang the eaves by 6-10 mm and the rakes where applicable.

Application instructions

Easy application (for professional roofers):

- Base is a wooden or concrete underdeck construction with a waterproof IKO underlayment.

- Apply roof shingles with IKO nails.

- You would need +/- 35 pc/m². Valley, hips and ridges are easy to install without purchasing a huge range of extra accessories.

Foresee solid insulation and also good ventilation for an optimal and long-lasting roof - improving heating and cooling costs.

Eaves, rakes, walls, chimneys, roof windows, etc. require metal flashings.

Shingles roof with slate tile look and feel

The Monarch Diamant roof shingle is a popular alternative for slate tile roofs. Especially when you choose for the black or grey (slate) colour, the Monarch Diamant roof shingle offers the same look and feel as the classical slate roof tile, but with a few advantages. The Monarch Diamant roof shingle is more price economical than a slate tile roof. A full shingles roof is also much lighter than a slate tiles roof, which is both easier for application and an important issue when choosing your roof deck material.

Calculate how many shingles and accessories you need for your next project!

Monarch Diamant, the thicker roof shingle with glassfiber inlay

The Monarch Diamant is the thickest roof shingle in the wide IKO range. Although thicker does not necessary means better, choosing for our Monarch range is definitely one of the best choices you can make. This higher quality offered by this stylish roof shingle is reached in two ways. First of all, we use a thicker fibre glass inlay to ensure we create a durable and stable roof shingle. Another way the Monarch Diamant proves its great quality is the use of the highest number of APP modified bitumen in the entire IKO Shingles range. During the manufacturing process, we add ±1500 gr APP modified bitumen per m².