Search

Search

1419 results were found.

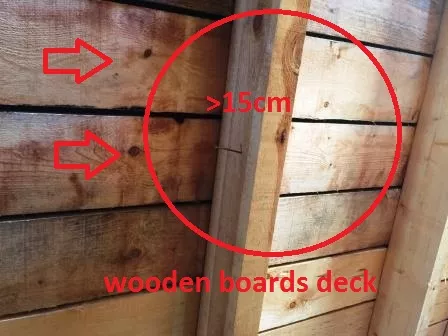

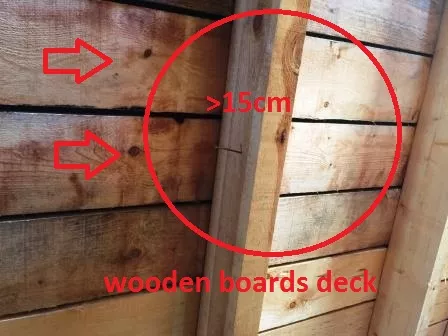

Vertical wrinkles

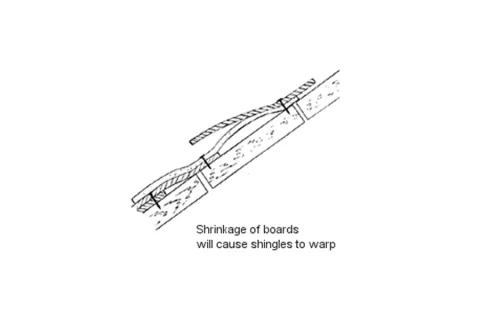

Shingle roof without ventilation

Shingle roof without ventilation

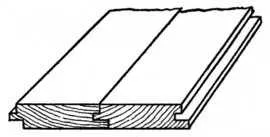

Tongue & groove joint

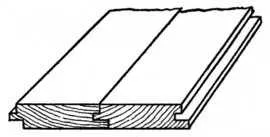

Shiplap joint

Tongue & groove joint

Shiplap joint