Search

Search

1419 results were found.

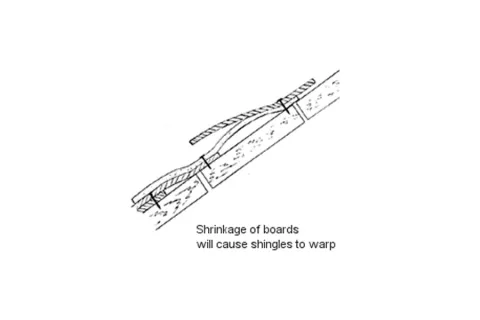

Roof decks that result in buckling of the overlying shingles are typically made out of lumber (also known as “board” or “plank” decks). Wooden boards or planks shrink or swell depending on their moisture content. Adjacent boards on the deck, even though securely nailed to the roof rafters, can shrink or swell at different rates. Shingles nailed to these wooden decks are usually held in place by two rows of roofing nails, each row often fastened into two separate boards. This is often the case when the board width exceeds the shingle exposure, eg. 20 cm boards vs. 14,3 cm shingle exposure. Differential shrinking/swelling of adjacent roof boards can therefore result in buckling of the overlying shingles. Just put a paper on the table and slide the left and right side 2 mm to the center at the same time. The paper curls and the same can happen with shingles on a lumber deck roof.

Incorrect spacing between OSB boards

Shrinkage of boards

In areas known for extreme wind speeds, the installation of roof shingles and their accessories must follow all manufacturer recommendations. Then the roof or façade is covered with a full IKO warranty and Platinum warranty as well.

Easy to transport

Fast & effective roofing material