How to shingle a curved roof or cone-shaped roof

Installing shingles on a curved roof or cone-shaped roof details presents unique challenges that even experienced roofers may find demanding. Whether you're working on a modern architectural design or a historic structure, mastering the art of installing shingles on complex roof shapes can lead to impressive results.

Special roof details

Because of their flexibility, shingles are the ideal material for completing difficult roof constructions. From towers and domes to curved roofs and trapezium windows, shingles can be used on contemporary building designs as well as in sacral and monumental architecture. The ability to precisely cut them to fit unusual shapes often makes them the better alternative for detailed roofing.

The knowledge of the right techniques and the use of chalk lines are very important. With carefully executed preparation and correct calculation of the necessary chalk lines, it is often quite simple to cover the roofs over turrets, trapezium dormer windows, etc. with shingles.

Rounded, coned or turret type roofs are labor intensive due to the many cuts, joints and unique workmanship involved in these custom roof applications. Labor time and costs are approximately five times higher compared to a normal roof. In the case of a curved turret, the trick is to trim the shingles at an angle so the sides butt together smoothly.

Cambridge Xpress Dual Black (52) on curved roof details >>>

Installing shingles on cones, turrets, and special shapes

1. Preparation and Underlayment:

- Begin by applying IKO Armourbase Stick, a self-adhesive underlayment, directly to the roof deck. This underlayment seals around nails, reducing the risk of leaks that are common with the increased joints found in rounded roofs.

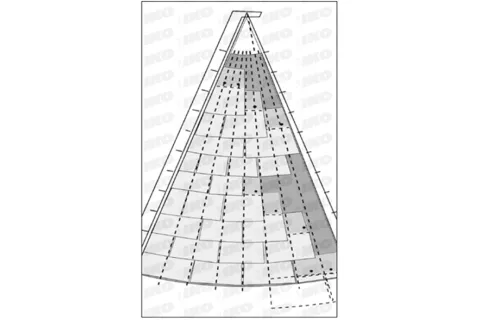

2. Shingle Cutting and Placement:

- The minimum width of a shingle should be at least half a tab.

- Trim shingles at the eaves to fit the curved edge.

- The length of the shingle depends on the circumference.

- Snap chalk lines from the peak center point to the eaves at intervals of one-half tab measured at the eaves.

- Gauging size to ensure that the shingles lay flat and fit uniformly between the chalk lines.

3. Adapting Shingle Size:

- As you move up the roof, shingle portions should become progressively smaller to match the narrowing circumference.

- Maintain a staggered side offset and align cutouts with every other course, following the chalk lines.

- Cut trapezoidal sections from shingles to fit between the narrowing vertical lines until the shingles are a minimum of half a tab wide at the lowermost edge of the shingle piece.

4. Precision and Stability:

- Each shingle piece should cover approximately three vertical lines. As the space between the lines narrows, increase the width of the shingle piece to cover five lines.

- Continue up the roof using wider sections when pieces become less than half a tab.

- Ensure cuts are straight to prevent gaps between joints.

- Secure each shingle piece with two nails and hand-seal with extra bituminous mastic.

5. Finishing Touches:

- For the peak, a metal cap or cone can enhance the appearance and simplify the finishing process.

Not sure if shingles are the right choice for your project?

Download our inspiration book and see how shingles fit with each style and shape!

Safety and Accessibility

Working on cone-shaped roofs can be hazardous due to their steep angles and height.

Safety should be a priority:

- Set up scaffolding around the base of the roof to provide a stable working platform. This will allow you to access all the areas, to store your shingle pieces and to lean a ladder onto the roof to support yourself on the cone while roofing it.

- Use IKO Roof brackets to improve movement and stability on the roof.

- Roofing a cone is labor-intensive and costly, so account for additional expenses, including scaffolding, in your project budget. It is faster and cheaper in the long run and will make the job come out better too.

By following these expert tips and techniques, you can successfully shingle curved and cone-shaped roofs, creating a stunning, weather-resistant finish that stands the test of time.

Take a look at the following before and after, to see how beautiful shingles can look on these types of roof.

Before shingle application

After - Application of Cambridge Xpress Dual Black (52)