Zoeken

Search

973 results were found.

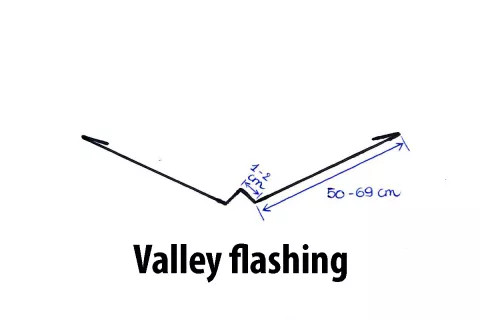

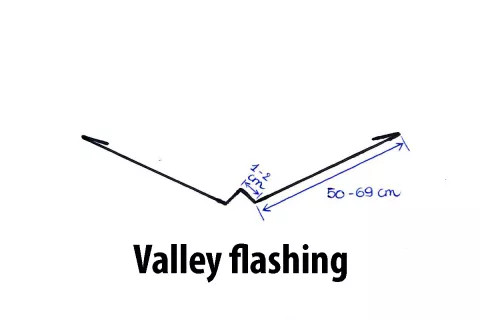

Metal valley option

Roof valleys are where two sides of the roof meet, which will be the case in any gable or hip roof that has multiple roof sections. One of the installation options for open valleys is the method with the metal flashing instead of a mineral-surfaced roll. The metal flashing for roof valleys should be minimum 26-gauge (0,45 mm) galvanized steel or equivalent non-corrosive, non-staining metal with a minimum width of 60 cm. If you apply the metal valley flashing with a splash diverter and water guards on the sides which are fixed with the metal cleats, 50 cm width is permitted. Performed “W” style valleys are preferred because the center crimp helps relieve stresses on the metal without forcing the metal to buckle. The “W” shape valleys help to brake and divert water on the sides.

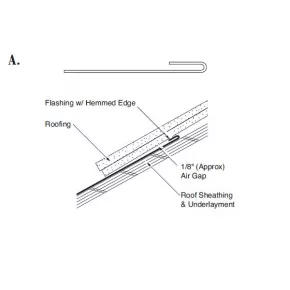

Special hemmed edges

Hemmed edges are used on most metal flashing systems. The hem or fold makes the flashing strong at the hem and helps control water flow. The hem can be turned up or down. Hems turned up are used at the high edge of flashings around roof penetrations, such as skylights, soil pipes and chimneys. Upturned hems are also used on the roof side of continuous sidewall flashings and on the vertical edge of open metal valleys. An upturned hem creates an air gap that resists the capillary migration of moisture from the metal to the roofing. They should never be hammered flat. Upturned hems also serve as hooks for attaching cleats. Downturned hems are used when flashings are lapped over the top of roofing or other materials, such as skylight glass.