Search

Search

1419 results were found.

4. Anti-block surfacing is then applied to the back of the sheet to prevent it from sticking to the machine and to other shingles when packaged.

A plastic tape is also applied to the back of the sheet to prevent the sealing strips from sticking to the next shingle in the package.

5. The granules are then pressed into the topcoating.

6. Once the sheet is cooled, sealing strips are applied. The sealing strips allow one shingle to bond to the overlying shingle on a roof and thus prevent wind uplift.

7. The roofing sheet is then measured and cut into shingles.

8. The shingles are wrapped into bundles and stored in the warehouse until they are ready to be shipped to the appropriate location.

Are you a professional and interested to see the production process with your own eyes? Contact us today for a plant visit.

Find your way to our plant in Slovakia or Belgium.

Download the printable Road Description PDF (at the bottom).

For you or your transport company.

For other practical questions, IKO is at your disposal.

Contact IKO.

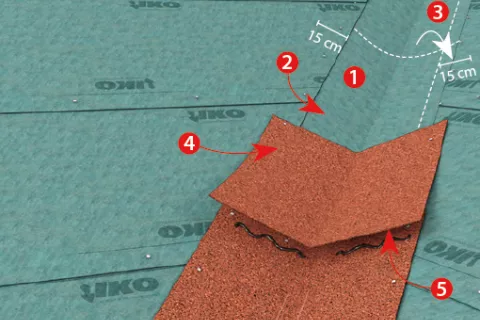

Quick guide application photos

Reroofing “The Westin Turtle Bay Resort & Spa, Mauritius” with IKO Cambridge 53 ^^^