Search

Search

1419 results were found.

So be sure to follow the recommended application method, in order to create an impressive end result on your roof and wall. Good luck!

Interested in one of the shingles mentioned in this article?

Order your A4/A5 sample here!

Interested in the product mentioned in this blogpost?

A question we get a lot is if it is possible to install skylights or roof windows in a shingles roof? The answer is simple: Yes! In this blog we’ll show you the steps how to install a skylight, but let’s talk skylights first!

Roof windows and skylights are very simple concepts with a lot of advantages. They are primarily bringing natural light to the attic and living space. This is perhaps the most important advantage, as sunlight is beneficial to our health, tone and mood. Adding a skylight will allow people to live more comfortably in relation to their biological clock.

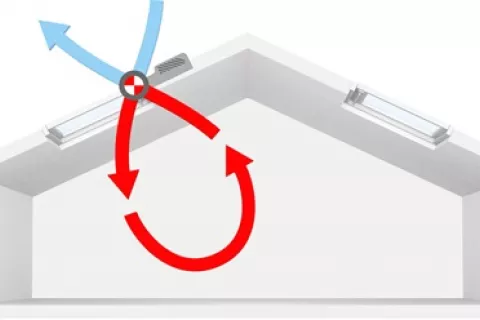

A second advantage is using natural light in your rooms and lowering the bills for electricity. Installing a vented skylight solves the problem of insufficient ventilation and lets the air move more freely and naturally, creating a fresher home aroma. The ideal place to install a skylight is a kitchen, bathroom or bedroom. This ventilation advantage also means saving electricity, as there is no need for you to use a kitchen or a bathroom fan.

Privacy can be another advantage as well. Often houses are located side by side and opening a window opposite to another window is not always convenient. Roof windows can bring natural light to your bathroom or bedroom, without sacrificing your privacy.

Types of skylights and roof windows

There are three basic types of skylights: fixed skylights, venting skylights, and tubular skylights (light tubes). A fourth variety, roof windows, is a type of venting skylight used where circumstances make it practical. Roof windows are bigger with the same orientation as the surrounding roof. They are typically used on roofs where the roof slope is more vertical.

Tubular skylights

Roof window

A lot of comfort has been included in recent skylight models. Today we know many motorized venting skylights, controlled with a wall switch or wireless with a remote control. Fully automated models come equipped with rain sensors, closing the skylight as soon as the first raindrops fall. Some of them even contain a small heat recovery unit or recuperation unit which delivers over 75% heat recovery of the exhaust air.

This way you can ventilate your home with fresh air during colder months without affecting your indoor temperature, avoiding unnecessary heat loss, cold draughts and heating bills.

<<< Skylight with heat-recovery unit

Replacement of a new skylight window to existing shingle roof

Installing a skylight in a safe and proper manner is above the average do-it-yourselfer level. It requires tools and experience in roofing and carpentry, a simple mistake might have huge consequences.

Often even experienced roofers think that the replacement of an old skylight window to an existing shingle roof can be a tricky job. But when a roofer follows the following simple but important guidelines and recommendations, the installation will be a success.

1. Remove roofing nails from shingles around the skylight and trim these shingles if necessary. It is always good to leave 30-40 cm working space around the skylight. It’s much easier to do this job when it is warm. Shingles are more flexible during warm weather. During cold weather it is difficult to unglue shingles and you can easily damage them. Sometimes it is good to use a hot-air gun and preheat the surface of the shingles to easy peel them off.

2. Dismantle and remove the old skylight together with metal flashing from the roof deck and install a new window.